Automation

Automation

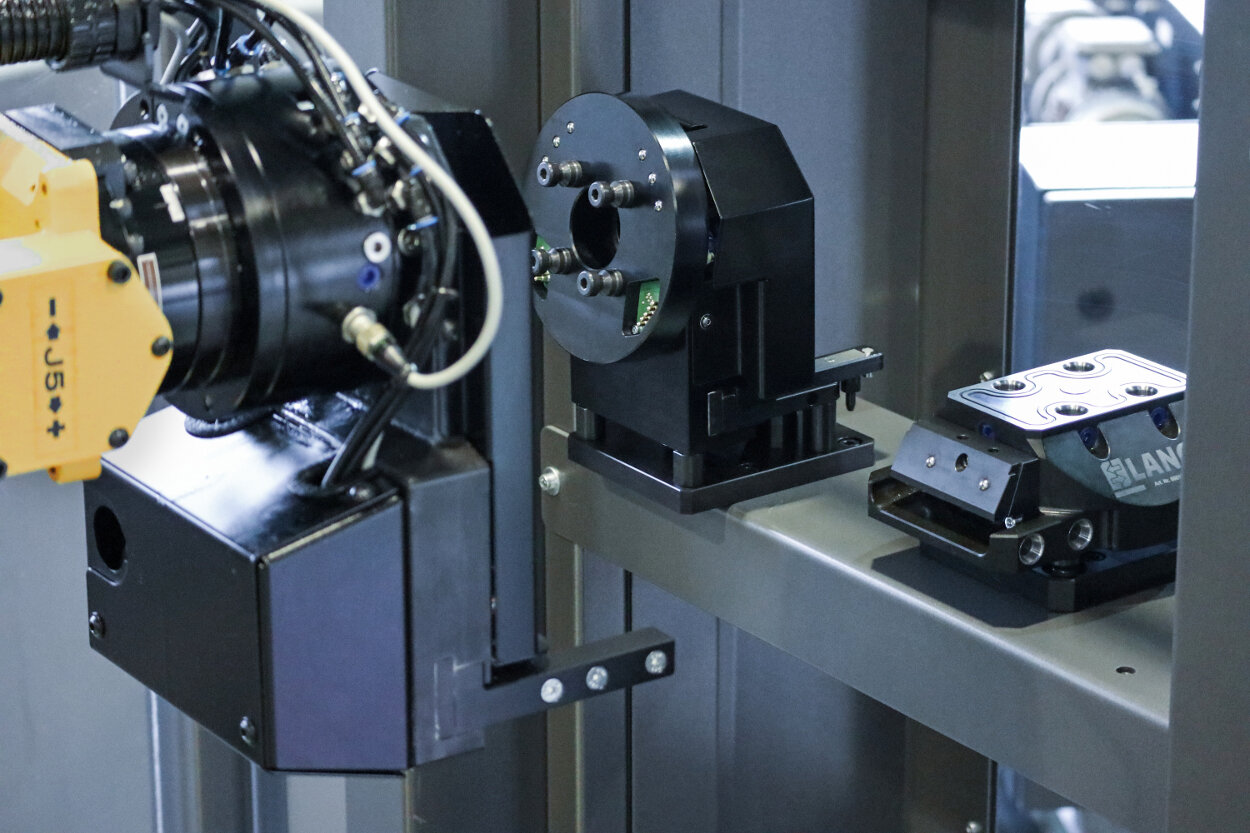

Even more options and flexibility when it comes to the variety of processable part sizes. Since summer 2020, LANG Technik has been installing an interface for a gripper exchange in the RoboTrex 96 automation system. This means that RoboTrex 96 is now able to work with the "smaller" RoboTrex 52 gripper and the associated components respectively (automation trolley, automation zeropoint device and Makro•Grip® 77 vices) and so both systems can be used at the same time to automate an even wider range of workpieces.

Especially when the weight of smaller workpieces exceeds 12 kg which is the maximum the RoboTrex 52 gripper can handle, the new option becomes a real alternative, since higher weights are possible. Analogous to the two gripper types, two different automation zero-point devices are used inside the machine. Here both may remain in the machine at the same time. The exchange between 52 and 96 mm system is conducted automatically by the RoboTrex 96 gripper which (un-)loads the "small" automation zeropoint device and stores it in the rack (see bottom left picture).

Alternatively, with a manual exchange of the zero-point devices only one may be placed on the zero-point base plate if desired.

In addition to the innovative gripper exchange LANG Workholding now offers a pneumatic gripper version for RoboTrex 52 as well.