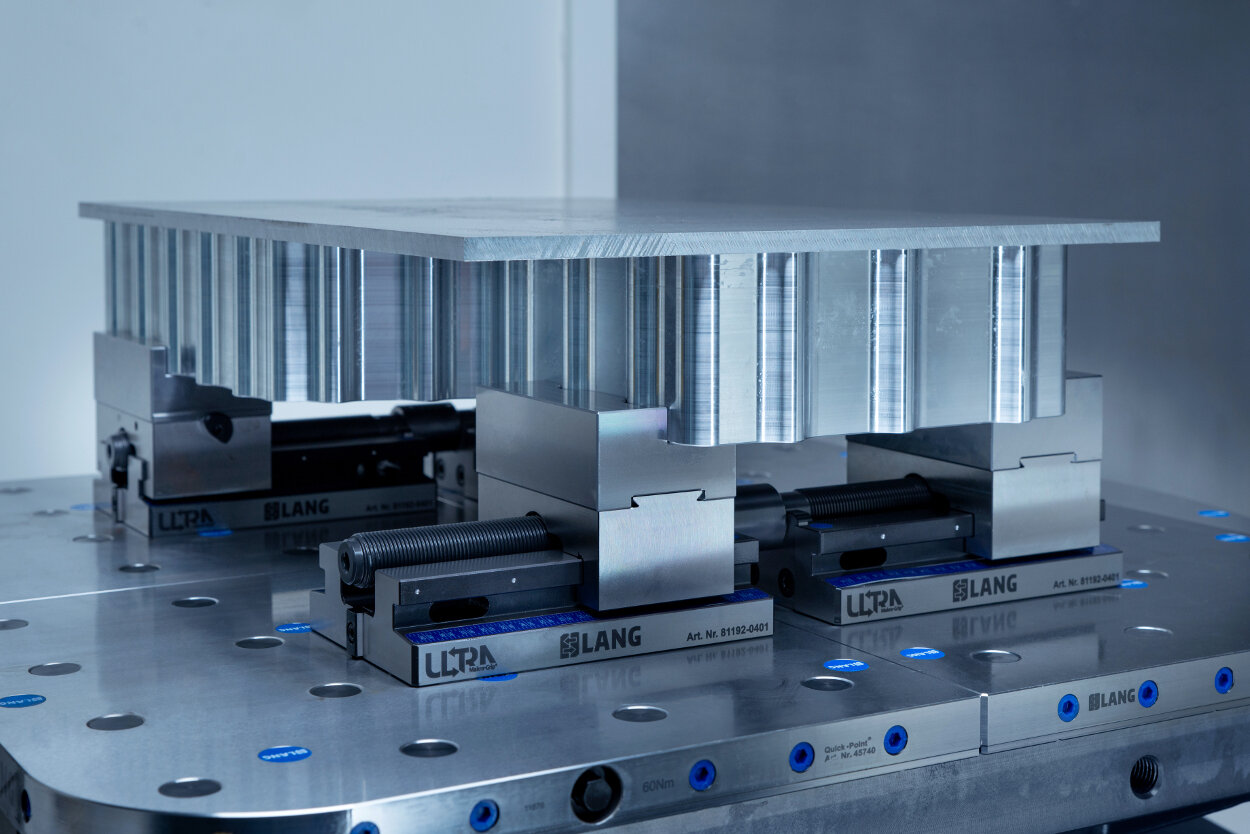

Makro Grip Stamping Unit

Makro Grip® Stamping Unit

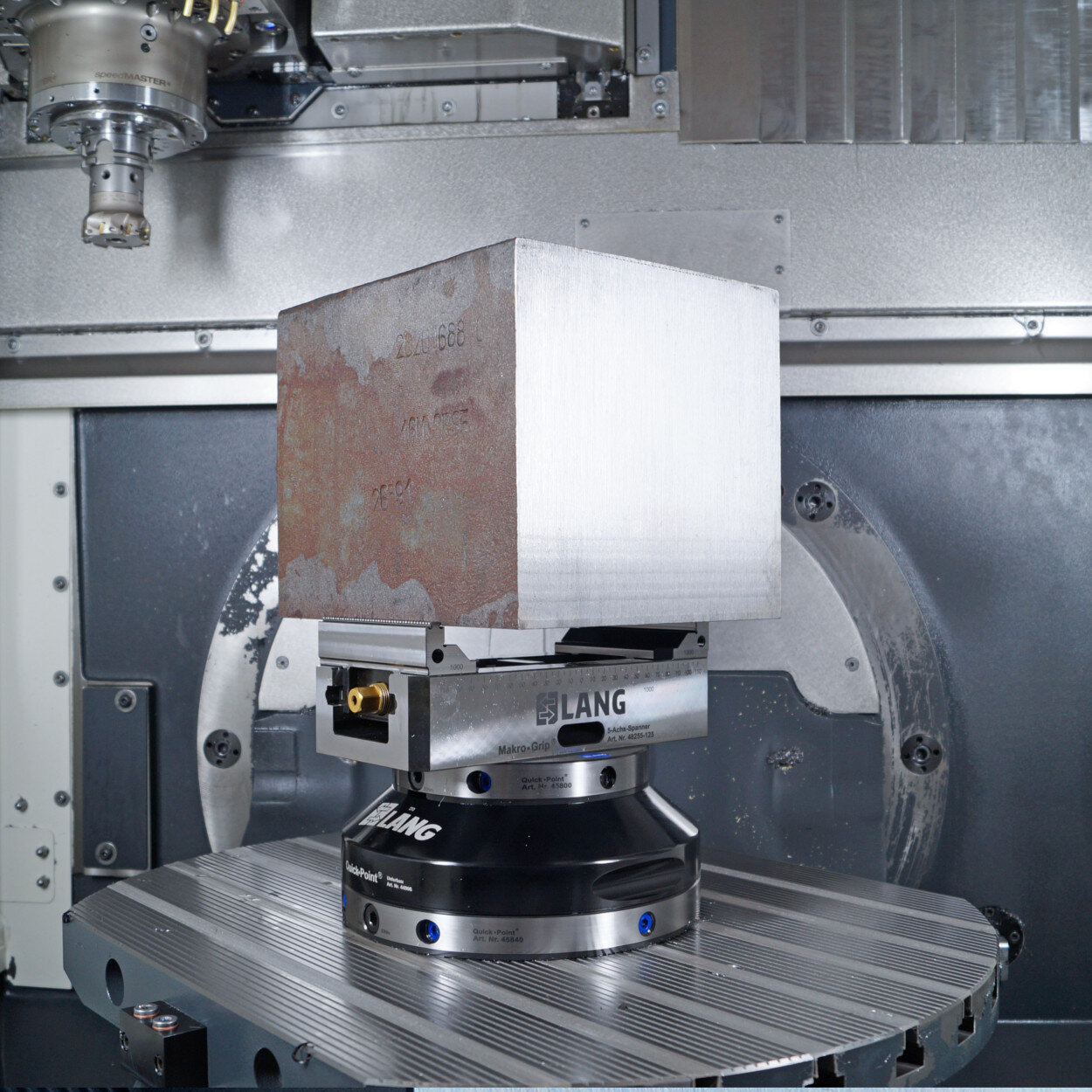

Form-Closure Technology refers to a technology in which the workpiece to be clamped is “pre-stamped” with a defined contour under high stamping pressure (up to 20 t) outside of the machine tool, before it is clamped in the clamping device.

Due to the great amount of advantages for the actual clamping process through “pre-stamping”, the Makro•Grip® technology is considered a benchmark in the5-sided machining of blanks and absolutely beneficial to automated

Why pre-stamp a workpiece?

The form-closure effect between the gripping serration of the clamping jaws and stamping indentation guarantees highest holding forces and maximum process reliability at a very low clamping pressure. This practically eliminates any material deformation which is crucial to clamping flat and deformation-sensitive material and a key factor in achieving the

desired milling quality. The stamping technology completes the Makro•Grip® Ultra system and raises the quality of plate and large part clamping to a new level.

The Makro•Grip® Ultra stamping unit is available in three different sizes. Fundamentally they are identical, but differ in their base plate’s size and number of grooves and locking holes. The system is designed as a dual-stamping unit which can be placed flexibly in the 96 mm grid of the base plate. The stamping unit is operated conveniently via push button. Included in delivery are two different sets of parallels which match the clamping depth of the serrated Makro•Grip® Ultra clamping jaws (3 mm and 5 mm).